The Best Strategy To Use For Plant Conveyors And Systems

Table of ContentsMore About Plant Conveyors And SystemsAbout Plant Conveyors And SystemsMore About Plant Conveyors And SystemsPlant Conveyors And Systems Things To Know Before You BuyAn Unbiased View of Plant Conveyors And Systems

They typically have a system of gears run by an electric motor. Variable rate drives have actually ended up being preferred for contemporary communicating considering that they permit adjustments of product circulation. Safety and security: Conveyor systems are regulated by the Occupational Safety and also Wellness Management (OSHA) as well as should satisfy government safety needs. All conveyor producers understand the policies and also abide by them.Belt Conveyors Belt conveyors are one of the most typical and simplest form of conveyor and also can have variable rates. They have a moving belt that rests on a steel frame that supports the belt and also the products being moved. Ones that have a sustaining framework underneath are described as moving design.

Gravity Roller Conveyors Gravity roller conveyors have a collection of similarly spaced rollers linked to a side frame. If a gravity roller conveyor is slanted or installed on an angle, materials move by gravity.

Chain Conveyors Chain conveyors can have 2 or a number of collections of chains that make contact with all-time low of items to be moved - Plant Conveyors and Systems. The products remainder on the chains as they are moved. Chain driven conveyors are ideal for products with uneven lower surfaces or ones that are extremely heavy.

Not known Facts About Plant Conveyors And Systems

Due to the kinds of items chain conveyors relocate, they run very gradually. Motorized Roller Conveyors Motorized roller conveyors make use of motors, put along the conveyor frame, to power evenly spaced rollers. The design is comparable to a gravity conveyor with the addition of motors. The variety of electric motors hinges on the tons to be moved and also the total layout of the system.

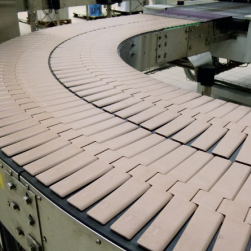

In some systems, there is a sensing unit that begins as well as stops the electric motor to avoid items getting packed with each other. Slat Conveyors Slat conveyors have the very same style as chain conveyors with level slats linked to the chain. Somehow, they resemble belt conveyors with slats replacing the belt.

The room shields the track from wear and also makes it easier to position bends as well as contours in the system. Open Track Conveyors - Open up track conveyors do not cover the track and usage I beams as the track. They are simple to install as well as suitable for long straight setups. Chain Overhead Conveyors - Chain overhead conveyors make use of a continual powered chain that leaves a track.

In various other layouts where pendants are not made use of, Clicking Here pusher pets might be utilized discover here to move trolleys along a second track positioned beneath the chain track. This kind of system is referred to as power and also complimentary. Monorail Conveyors Monorail sharing systems have service providers to move products and also are perfect for use over cross countries.

Plant Conveyors And Systems Things To Know Before You Get This

Monorail conveyors make use of the space above the production area. In some designs, the carriers lower to the degree of manufacturing and after that go up, off the beaten track. Power and Free Conveyors Power and complimentary conveying systems are created to relocate parts with the production as well as setting up procedure.

They stop at each station to be dealt with as well as then move on. Power and free systems are a special type of overhead sharing system. The distinct design of power and totally free systems permits an item to be buffered along the conveying path, begin as well as stop automatically, and also are extremely versatile and also adjustable.

Upside down Conveyors Inverted conveyors are flooring mounted and also can be utilized as power and totally free conveyors. They generally have a drive system that does not entail a belt or chain. Paternoster Conveyors Paternoster conveyors are a vertical sharing system that utilizes equivalent spaced lots service providers linked to a chain drive, which relocates in a continual loop (Plant Conveyors and Systems).

Plant Conveyors And Systems Things To Know Before You Buy

The chain can flexing along the horizontal axis enabling it to make straight turns and also is capable of making upright contours. The different kinds of weaves a COE makes enables it to be much more versatile than typical chain driven conveyors. Skid Conveyor Skid conveyors are an additional type of flooring mounted conveyor that relocates items on fixtures that have actually longitudinal joggers called skids with travel being longitudinally and transversely.

Skid conveyor systems are valued for the effectiveness as well as peaceful setting of transportation. The variants in skid conveyor systems are due to the numerous components and control systems that can be consisted of. Rubbing Conveying System A rubbing conveying system utilizes a motor to drive a rubbing wheel made from non metallic product to develop driving pressure.

Rubbing conveying systems are a try here safe choice to power and also totally free systems with the major advantage of operating cleaner and also quieter. They have a versatile design, unit construction, simple rate transforming, can conveniently be expanded, and low general expense. The primary objective for rubbing conveying systems is to assist with operations that have a high manufacturing price.

3 Simple Techniques For Plant Conveyors And Systems

When the electric motor is triggered, the belt is pulled in between the pulleys. Support group: The support group allows the belt to move smoothly. It is specifically developed to hold the moving material without sagging. In the design phase, the weight capacity of the framework is determined as well as the structure is built to meet the demands of the procedure.